Category

4 Color Manual Silkscreen Machinery Octopus Rotary Silk Screen Printing Machine

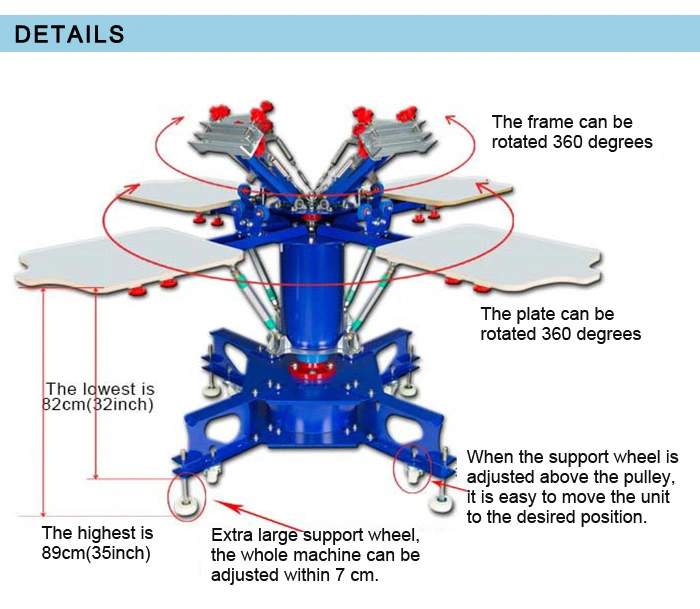

The frame chuck part and the platen part can be rotated 360 degreesfreely; the operator can operate in any position or a

Basic Info.

| Model NO. | MK-F442E |

| System Supported | Manual |

| Packing Quantity | 1 |

| Gross Weight | 134kg |

| Attachment Material | Stainless Steel or Zinc Plating, Nickel Plating |

| Machine Surface Treatment | Electrostatic Spraying |

| Using | T-Shirts Silk Screen Printing |

| Color and Station | 4 Color 4 Station |

| Packing Volume | 0.34m3 |

| Packing Size | 110*55*56.5cm |

| Product Color | Blue |

| Model | Mk-F442e |

| Machine Using Material | Steel Plate |

| Printing Area | 22in(55cm)*18in(45cm) |

| Product Name | 4/4 Manual T-Shirts Screen Printing Machine |

| Other Name | Rotary Carousel Printer |

| Product Code | 070004 |

| Transport Package | Export Carton |

| Specification | 22in(55cm)*18in(45cm) |

| Trademark | MACROKUN |

| Origin | China |

| HS Code | 8443192290 |

| Production Capacity | 10000/Year |

Product Description

| Product Code | 070004 |

| Product Name | MK-F442E floor type 4 color 4 station double wheel screen printing machine |

| HS code | 8443192290 |

| Product Color | blue |

| Printing Area | 22in(55cm)*18in(45cm) |

| Machine using material | steel plate |

| Machine Welding Technology | Welding mainly |

| Machine surface treatment | Electrostatic spraying |

| Important components | Aluminum profile |

| Attachment material | Stainless steel or zinc plating, nickel plating |

| Packing quantity | 1 |

| Net weight | 107kg |

| Gross weight | 134kg |

| Packing size | 110*55*56.5cm |

| Packing volume | 0.34 m³ |

| Packing material | Export wooden box |

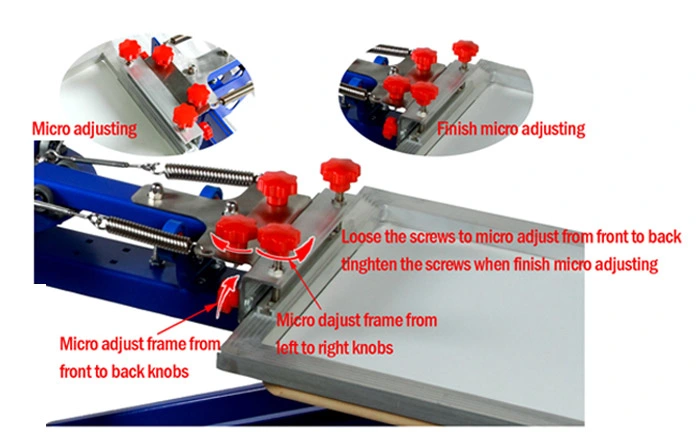

The silk screen frame clamp can adjust the spring tension by screws according to the weight of the frame to achieve the most suitable balance pull-out tension.

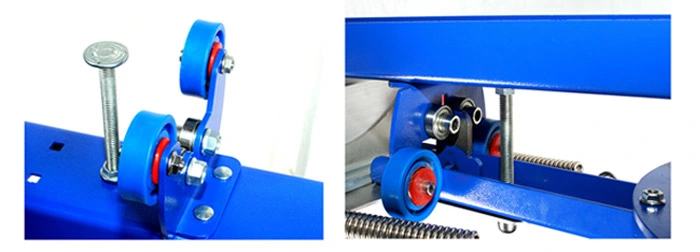

The platen can be moved back and forth through the bottom connector.

The hex support rods with adjustable reinforcement are installed on the lower part of each platen. The user can rotate the hex support rods to strengthen the stability of the platen and adjust the parallelism to ensure the platen is more stable and the printing is more accurate.

The frame clamp width is 26 (10in) cm; suitable for various frames within the frame outer diameter of 60 (23in) cm and the frame thickness of 5 (2in) cm.The chuck can be adjusted upwards by 3 cm depending on the height of the substrate.

The T-shirt type platen of this machine is 55 cm (22 in) long, 45 cm (18 in) wide and 1.8 cm (0.7 in) thick. |t is made of melamine high-density furniture board with a fine surface.

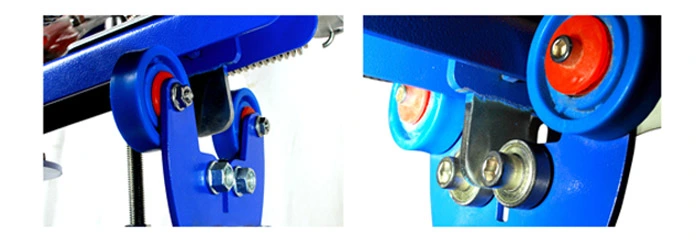

This machine is equipped with support wheel and moving roller. By adjusting the screw of the support wheel, the level of the whole machine can be adjusted and the whole machine can be adjusted in height within 7CM; when the screw of the support wheel is adjusted to the top When the whole machine is supported by he moving roller, the whole machine can be easily moved.The machine adopts advanced electrostatic spraying process, various parts using stainless steel, aluminum alloy, nickel and zinc plating technology. They are corrosion resistance, no fading, easy to clean, maintain color and finish for a long time, and it can use for a long time with no rust.All machines are configured with a full set of tools to install the machine; There is no need to prepare for other tools to complete the installation; Equipped with installation diagram and the packing list, parts installation location is very clear; All machines are configured with installation CD and operation video, it is more convenient for the user to install and use the machine .There are still spare parts in the box for users to change.